Head Office

Risehow Hydraulic CenterFlimby, Maryport CA15 8PA 01900 816000

Leconfield Office

Leconfield Industrial Estate Cleator Moor CA25 5QB 01900 816000

Barrow Office

Flass Lane Barrow in Furness LA13 0GW 01229 486276

Risehow Hydraulic CenterFlimby, Maryport CA15 8PA 01900 816000

Leconfield Industrial Estate Cleator Moor CA25 5QB 01900 816000

Flass Lane Barrow in Furness LA13 0GW 01229 486276

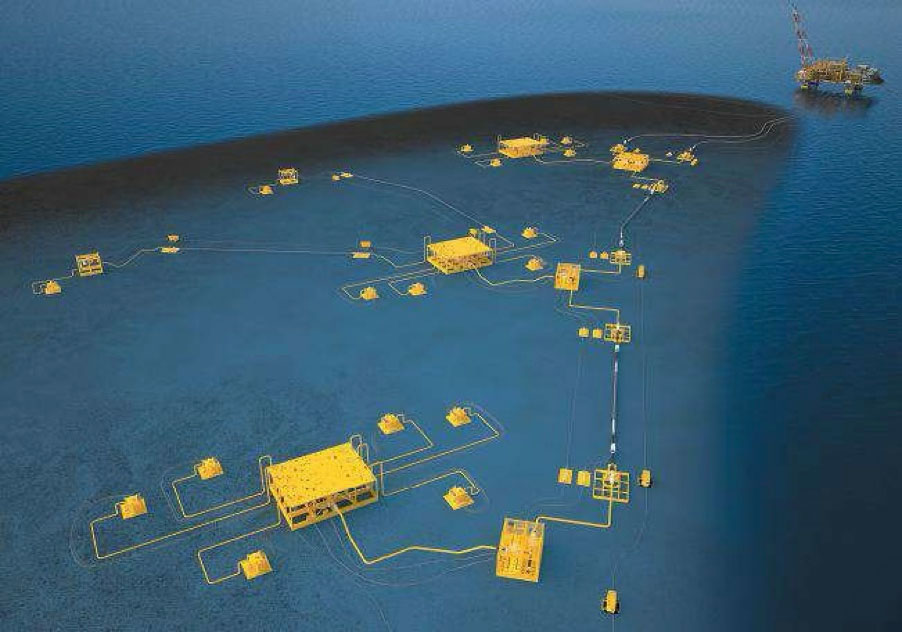

Forth delivers innovative engineering solutions to the Oil & Gas sector globally, specialising in advanced remotely deployed inspection, maintenance, and decommissioning technologies.

We are dedicated to enhancing safety, operational efficiency, and sustainability across the offshore asset lifecycle.

Our expertise includes specialised technologies such as modular pig retrieval tools designed for safe and swift pipeline maintenance, and the Restricted Access Inspection System, enabling precise detection of defects in hard-to-access infrastructure like caissons.

Additionally, our CHIMERA platform, a semi-autonomous robotic system, revolutionises internal pressure vessel inspections by significantly reducing downtime, cost, and risk, ensuring compliance with rigorous industry standards without compromising containment integrity.

Through continuous innovation and collaboration, Forth sets new benchmarks in safety and efficiency, helping operators maintain and extend the lifecycle of critical Oil & Gas assets.

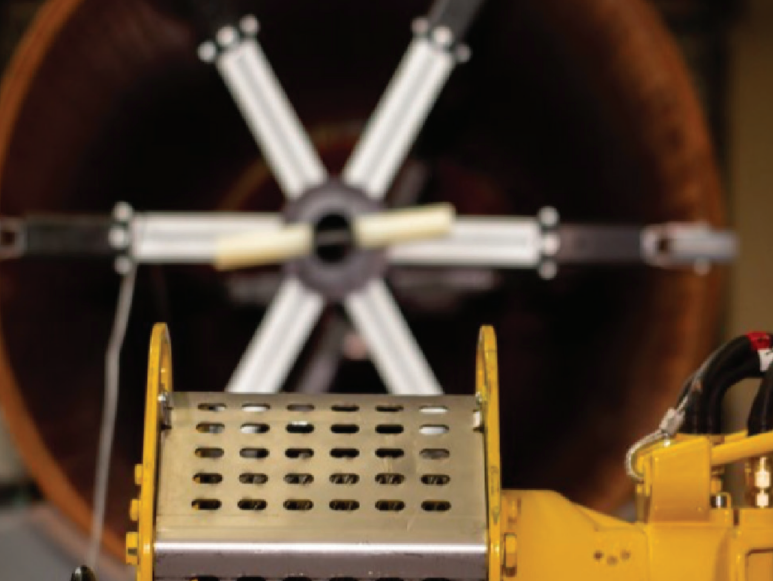

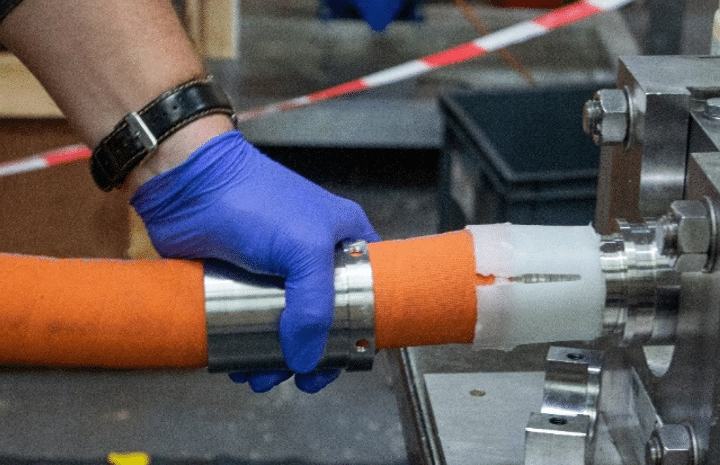

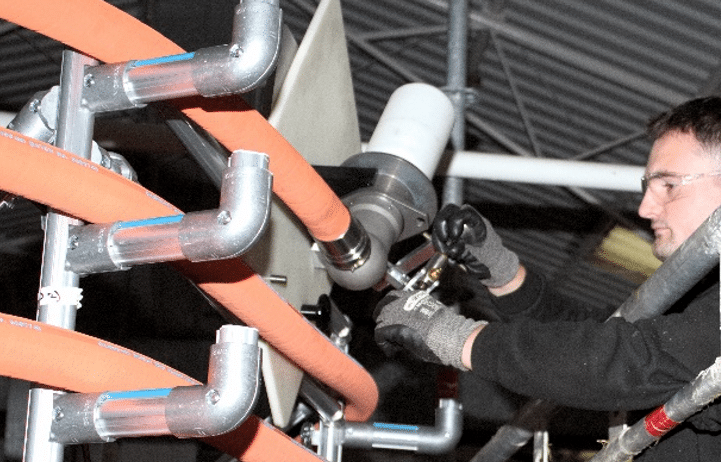

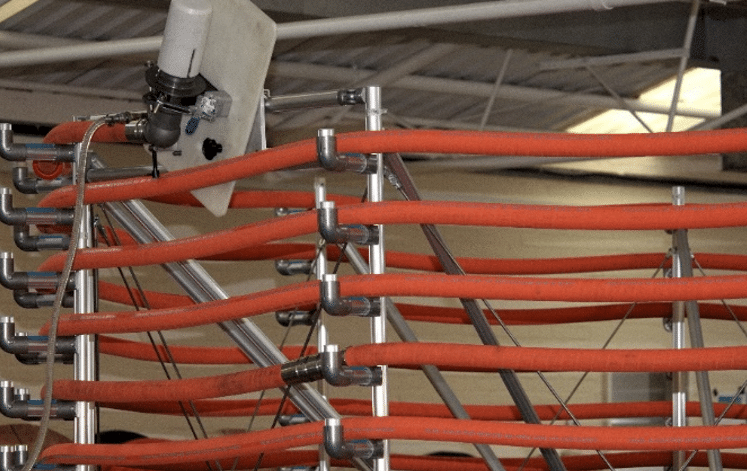

The following are pictures of Power EFL’s being assembled at Forth

Forth developed a modular tool spread that integrates an ATEX Zone 1 pneumatic winch to a receiving cradle for the pig, which is then coupled to a lightweight, self-supported and centralised long reach grabbing device (adjustable up to 15m), using an auto locking grab at the front of the assembly, which latches to the pig upon contact with the pig’s latching point.

This is used in tandem with a front mounted ATEX Zone 1 camera linked to a topside viewing monitor, to provide a feedback loop to the operator, which reduces manual handling and operating time to allow swift return to production as well as improving the ultimate safety of the process.

Our team built a pioneering, remotely controlled Emergency Response Robot capable of withstanding hazardous environments on a 1.6 tonne JCB compact excavator platform and fitted with a specialist robotics system and wireless technology.

The robot is capable of towing a trailer with a fitted hopper that can disperse a bund of sand to contain any type of spillage, and it also has an affixative spraying system attached that is used to assist in the containment of a nuclear spillage.

Other features include a large grapple hook that will be

used to move any obstruction the robot may come across, as well as a specialist 700bar rescue tool to cut through any obstacles.

There is a demand in the market for innovative and efficient ways to support lifetime extension programmes of existing assets and infrastructure. One key area is the asset caisson (seawater inlet, outlet pipes) which suffer from excessive corrosion and fatigue life problems.

Forth can provide the next level of technical solutions for

accurate, reliable detection of aging caisson defects.